Why is it important to choose the right thermal management system?

Choosing the right thermal management system for the batteries of electric vehicles is crucial to address electrical energy used by electric ancillary components to cool down or heat up vehicle systems including powertrain and cabin.

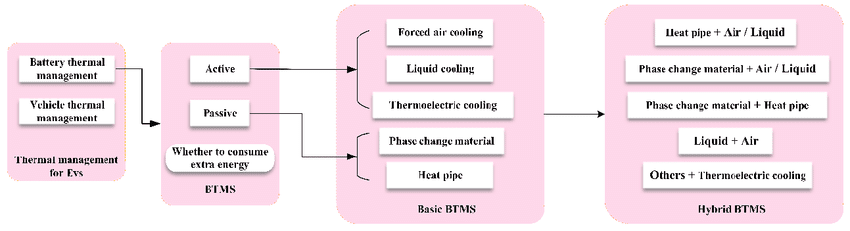

All the battery cooling technology systems available today

First, what is the difference between Passive or Active BTMS?

Passive BTM Systems will operate from natural or external forces and sources of energy (e.g. gravity, latent heat, or vehicle motion), and as such do not directly require electrical energy from the vehicle.

Active BTM Systems will use electricity with a given efficiency, which ultimately translates to ancillary losses and therefore costs to the system.

Active BTMS

Forced air cooling

In this system, a fan is used to generate airflow, which directly passes through the battery pack to extract its operating heat. Forced air cooling is considered a low-cost solution. Its low cooling capacity may lead to lower temperature uniformity and hot spots.

Example of vehicle using force air cooling:

- Volkswagen eGolf

- Nissan Leaf

Liquid cooling

Liquid cooling implies the use of a liquid to extract heat generated by the cells in cooling mode, either in direct or indirect contact with the cells.

Different types of liquids can be used:

- Coolant cooling (e.g. Water/Glycol mixture)

- Refrigerant cooling (e.g. 1234yf, CO2)

- Immersion cooling with dielectric liquid (e.g. hydrocarbon based oil)

Example of vehicle using Liquid cooling:

- BMW i3 (refrigerant cooling)

- Tesla Model S (coolant cooling)

- McLaren SpeedTail (immersion cooling)

Coolant cooling

Coolant cooling is the most common battery thermal management system technology deployed nowadays on electric passenger car vehicles.

This BTMS uses a water/glycol mixture as a coolant medium, flowing through channels as part of a specific fixture design (e.g. typically one or multiple aluminium cooling plates, or a flexible serpentine fixture as seen on the Tesla model S for example).

The battery pack heating is also provided by the coolant, while heat sources and heating strategies can widely vary from application (e.g. waste heat recovery from other powertrain systems or direct heating of the battery coolant through PTC heater for example).

Coolant cooling is an efficient system for several reasons:

- It is more compact than most air-cooling architectures and offers increased efficiency and cooling power;

- The potential for advanced vehicle thermal management system integration with one-fluid-for-all

- Possibility to integrate complex valve systems to direct heat where it is needed in the system (example with Tesla Octovalve)

However, coolant cooling also features some drawbacks:

- Limited cooling power compared to more advanced solutions, and hence limited fast charging capabilities

- Challenges with battery pack temperature distribution and resulting impact on battery life cycles

- Challenges with safety and thermal runaway propagation

Example of vehicles using coolant cooling:

- Tesla Model S

- Audi e-tron

- Chevrolet Bolt

Refrigerant cooling

A refrigerant cooling solution consists in integrating an evaporator within the battery pack in most direct contact with the battery cells or modules.

It promotes a much higher cooling capacity compared to cold plate, through the use of refrigerant latent heat, while some of the challenges include implementation on large batteries (evaporation controls) or heating mode.

Exemples of vehicules using refrigerant cooling: BMW i3

Immersion cooling

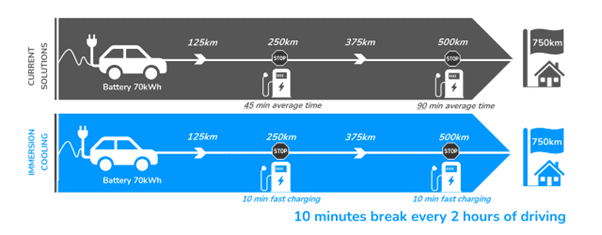

Through direct cooling of the cells and busbars, immersion cooling offers a minimised thermal resistance from cell to cooling fluid, largely overcoming the reduced specific capacity of dielectric fluid compared to water-glycol mixture, and hence enabling ultra-fast charging for BEVs.

Immersion cooling helps control batteries temperature distribution in a narrow range, offering extended life cycle.

With the right design, EXOES has demonstrated that thermal runaway propagation can be prevented, even in the absence of active cooling (e.g. pump failure), and with all possible cell form factors.

Comparison of driving/charging cycles for BTMS immersion cooling vs. Cold plate cooling

Passive BTMS

Passive BTM Systems will operate from natural forces and sources of energy (e.g. gravity, temperature), and as such do not require electrical energy from the vehicle.

Passive Air Cooling

It is the simplest approach to battery cooling. Using conduction through battery and vehicle mounts, as well as natural convection within the battery pack, it transfers the heat generated inside the pack to the environment with no, or limited (e.g. ducting), additional hardware.

This solution provides very limited cooling power and so can only be considered for low charge / discharge power applications

Example of vehicle application: Nissan Leaf 24kWh battery relies on ducted air cooling

Phase Change Material (PCM)

Cooling relies on latent heat of fusion from the chosen PCM. Numerous types of PCM are available with melting point tailored to the application requirements, ranging from paraffins to metallic alloys.

They are suitable for absorbing heat rejection peaks, locally for example, in order to provide greater uniformity in temperature distribution.

However, PCM are limited for repetitive usage (transient application) as they require material recharging. Phase Change Materials also come with a significant additional weight.

Heat Pipes

Heat pipes are a closed system containing a working liquid in balance with its vapor. Working fluid can be water, although other organic solutions with a lower boiling point may be suitable, depending on hot source temperature (e.g. ammonia, ethanol).

Heat pipes have 3 main advantages:

- Low-cost solution

- High cooling capacity

- Efficient for transferring cell heat

Hybrid BTMS

Hybrid Battery Thermal Management Systems take advantage of the benefits of both active and passive systems.

For example, PCM can typically be combined with cold plate cooling solution to achieve an improved temperature distribution, using PCM to address local hot spots, and the cold plate cooling solution to extract most of the battery pack generated heat under steady state conditions.

Although these BTMS systems demonstrate a greater performance, compared to standalone solutions, their complexity and cost are a limiting factor for implementation in electric vehicles.

Performance Comparison of EV BTMS

We have rated every system from 0 to 5 according to 4 criterias:

- Cooling

- Heating

- Fast charging

- Safety (prevent thermal runaway propagation)

| Air cooling | Forced air cooling | Coolant cooling | Refrigerant cooling | Immersion cooling | PCM | Heat pipes | |

| Cooling | 1 | 1.5 | 2.5 | 3 | 5 | 2 | 2 |

| Heating | 1 | 2 | 3 | 1 | 5 | 1 | 1 |

| Fast Charging | 0 | 0 | 3 | 3.5 | 5 | 1 | 1 |

| Safety (prevent TR propagation) | 0 | 0 | 0 | 0 | 5 | 0 | 0 |

Immersion cooling dramatically improves the battery thermal management from conventional solutions, enabling:

- Ultra-fast charging in under 10min;

- Increased safety with no propagation of thermal runaway, and no fire;

- Extended battery life thanks to greater uniformity and control on battery pack temperature distribution.

For more information about immersion cooling technology for EV battery thermal management, watch our latest webinar (+450 attendees 💥):