Your need ?

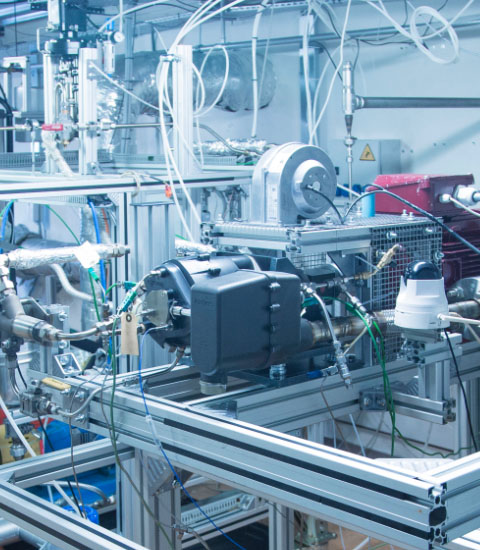

Your need: to find testing equipment with a high degree of accuracy to measure physical phenomena on prototypes, 5 years before they are put on the market. Most of the time, these tests are dangerous: batteries, flammable fluids, hydrogen fuel cells and they require teams with special skills and proven know-how. These specific benches are rare and usually have to be adapted to perfectly meet your thermal management needs.

Our contribution :

EXOES has extensive experience in the design, manufacture and use of complex test benches. We characterise components of thermal, fluid, thermodynamic, mechanical, electrical and electronic systems. We are able to offer a number of tests that our customers consider dangerous:

We have an in-house center for testing and simulating energy systems for on-board applications.

By coming to EXOES, you are guaranteed to have test results for your innovative application that meet the automotive sector’s parameters. We provide you with high quality tests in record time when the normative framework does not yet exist. And we can participate with you in setting standards for future normative testing.

Come to us with a concept and together we will define the complete validation program. We will design the prototype, the test bench – if this is specific – we will carry out the tests and the detailed analysis of them. We will then provide you with our recommendations for industrialisation.

The finesse of the analyses of our best thermal engineers brings our customers more than just data: it beings customer benefits that are demonstrated in relation to the latest developments. This valuable data is used by our customers for both advanced technical development and marketing purposes.

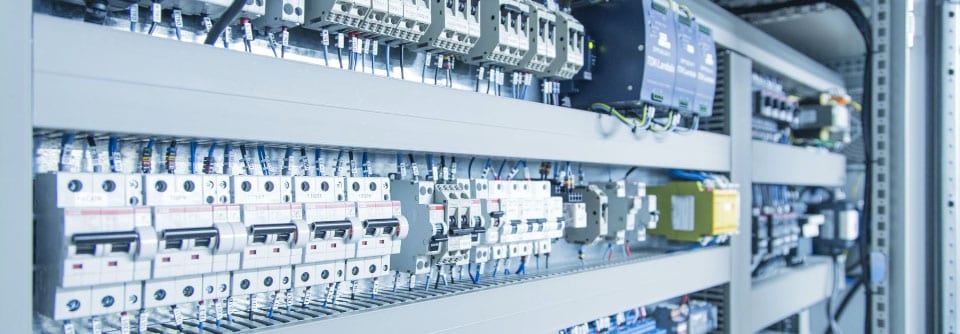

At EXOES, a bench generally consists of:

– A prototype to be tested

– A mobile acquisition chassis managing the security, acquisition, control and support of the prototype. In addition to the extensive instrumentation of temperatures, pressures, flows, voltages and currents, the benches can be equipped with high-speed cameras and thermal imaging cameras. This frame may include a linear actuator equipped with a nail for nail penetration tests or a power contactor for short circuit testing.

– This chassis can be moved to a secure test area, such as a climatic chamber, equipped to handle explosive atmospheres and battery fires

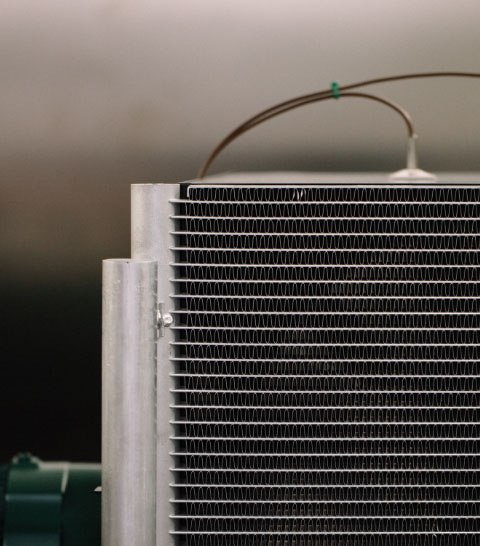

– A temperature-controlled fluid conditioning loop

– A bi-directional power electronics system to power the prototype and enable it to perform electrical cycling. Coupled with a junction box, it ensures electrical safety via a BMS as well as the precise measurement of electrical parameters

impedance scanning at different temperatures and SOCs, welding resistance measurement, cell disassembly and analysis of internal geometry, material compatibility, etc.

Cooling and heating performance tests on single cells. On battery modules: measurement of pressure drop, thermal conductance, overheating and temperature uniformity

Lithium-ion battery abuse tests: external heater, overcharge, short circuit, nail penetration on cells and modules (up to 10kWh) with active cooling or not

Climate chamber ageing tests of batteries in calendar and cycle operation.

Characterization of fluids used in immersion: measurements of heat exchange coefficient, pressure drop, critical flux in evaporation

Comparative studies between different cooling systems: thermal inertia, air, cold plate, single and two-phase immersion, spray, heat pipes, pumped two-phase loops, micro-evaporators, etc…

The system approach developed by EXOES is key to the added value it brings to its customers. We have testing and prototyping capabilities on all the thermal management loops present in the automotive industry.

Chemical compatibility (metals, elastomers, polymers)

Temperature and pressure ageing of lubricants

Miscibility/solubility of refrigerant-oil mixtures

Comparative performance tests on a real loop (COP, capacity, compression and pumping power, etc.)

High temperature chemical compatibility and corrosion (metals, elastomer seals)

Temperature and pressure ageing of lubricants (viscosity, TAN, colour, particle count, etc.)

Complete characterization of expanders and coolant pumps on dedicated benches

Complete characterization of heat exchangers, in particular hot-air evaporators

characterization of complete Rankine systems:

- Mechanical or electrical production

- Heat source: oil or dynamic burner (hot air)

- Cooling source: temperature controlled air

Endurance testing is possible on all our automated and secure test benches for 24-hour operation

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.