In the coming years, you will gradually replace your thermal engine test benches with test benches for electric drive trains, batteries and cooling systems.

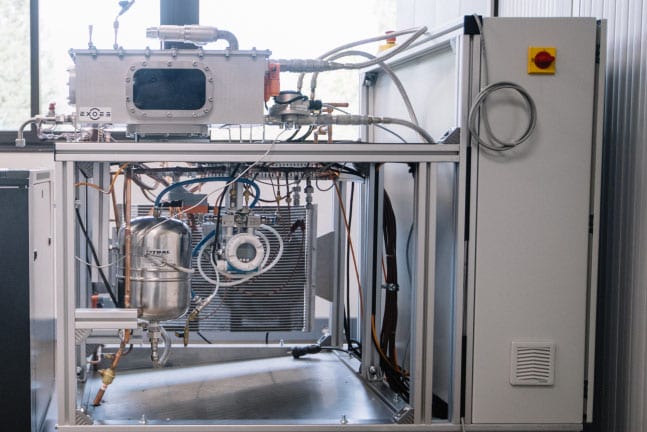

Since 2009, EXOES has been building turnkey test benches for its customers, from manufacturing to installation, all over the world. During a delivery, EXOES trains its customers’ teams to make them autonomous and independent while guaranteeing a high level of service and reactivity.

The bench, the prototype to be tested, your teams’ training:

at EXOES, you will have much more than a test bench!

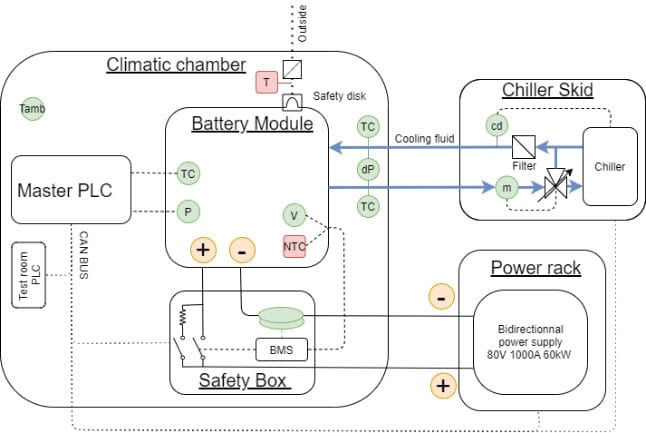

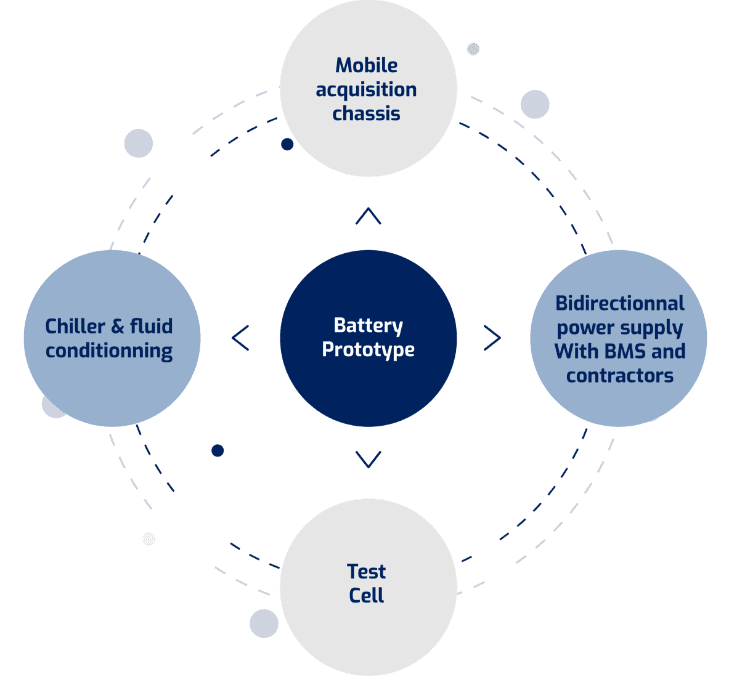

For its customers, EXOES develops the immersion cooled battery module or the complete battery pack as well as the test bench necessary for its operation, the measurement of its performances and its safety.

Example of synoptics of system benches developped by EXOES

– Thermal performance (cooling, heating)

– Abuse testing: nail penetration test, short circuit, overheating or overvoltage

– Ageing tests

– Training your teams

– Day-to-day remote troubleshooting

– Providing on-site maintenance

– Calibrating sensors

– Updating the control software and configuring the data acquisition system to follow the evolution of your test requests

Our test benches can be customised to your needs.

The design of prototype modules or complete immersion-cooled battery packs are also part of our core skills.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.