Your need ?

To have accurate simulations and reliable data, correlated with real data. If all the software give results, you are looking for accurate modelling with an excellent level of description of the physical phenomena.

Our solution:

To provide you with real data generated on test benches to characterize physical phenomena and correlate simulations.

Get reliable simulations powered by our test data

– 3D calculations in Gamma Technology Suite for cooling performance and thermal runaway propagation for cold plate and immersion cooled batteries

– 3D calculations in Gamma Technology suite for battery cell heating by modelling the internal geometry of cells

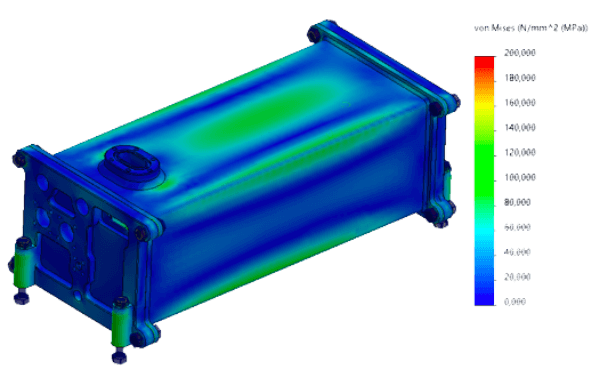

– Finite element calculations in Solidworks for mechanical strength, eigen mode, vibration and shock resistance

– Calculations in Solidworks for fluid flows coupled with heat exchange

– 1D calculations in Gamma Technology suite for pipe pressure losses

– 1D calculations in Gamma Technology suite for vehicles on test cycles

– Development of dedicated calculation code in Matlab and Simulink: Steam compressors, steam turbines, steam piston engines, …

Simulation is used at EXOES as a design and validation tool. It allows digital experimental designs to be created where testing would take too long and be too numerous and costly to obtain an equivalent quality result. This is possible if and only if the simulations are correlated, which is the case at EXOES.

An example of battery simulation: modelling prismatic, cylindrical or pouch cells for different electrochemicals: NMC, LTO, etc.

A complete electrical temperature test, carried out in our laboratory, allows first of all to characterize an electrical model of a temperature-variable RC cell. Afterwards, a complete dismantling of a cell is carried out in our premises. The geometry of the cell is reconstructed in 3D in SolidWorks and exported to GEM3D, the meshing tool associated with Gamma Technology Suite.

After simplification, a thermal model coupled with an electrical model is created. This cell model can either be used directly to determine the performance of cooling architectures (thermal inertia, air, cold plate, immersion, etc.) or be assembled into a module to study the propagation of a thermal runaway and the impact of different design options.

We adjust the velocities and pressure drops within the batteries and cooling loops. This allows us to distribute the fluid evenly and thus ensure temperature homogeneity and uniform ageing for the cells.

Simulation of air conditioning/heat pump system coupled with battery cooling:

– 0D/1D reversible refrigeration cycle model (heat pump) under GT Power

– dynamic 0D/1D model of battery cooling loop (liquid pumping / evaporative / spray cooling) and passenger compartment.

Simulation of air conditioning/heat pump system coupled with cooling of electrical motors or power electronics (inverter, charger, etc.)

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.