Understand what we can do for you through customer case studies: immersion cooled battery programs, vehicle integration, air conditioning system testing.

The customer is a European car manufacturer in the top 5 worldwide

Duration of the program: 22 months in 3 phases

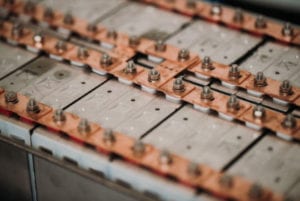

Cell type: NMC > 60 Ah

Role of EXOES before the beginning of the program: participation in the drafting of the specifications, advice and sharing of experience on the definition of the evaluation and validation program of different technologies and different immersion cooling fluids. Support for decision making on the split between simulations and real tests.

The customer’s need

-Define the ideal fluid for monophasic and diphasic cooling

-Carry out an evaluation of the series cost of a complete cooling system according to different cooling architectures

-Calculate the impact of different immersion cooling architectures on the mass of a vehicle

-Design a representative battery module

–Test this module in performance

–Test the module safety with an abuse test (nail puncture test)

–Define an ageing test protocol with several fluids

–Characterize the cell to determine the maximum C-rate at a defined maximum temperature

-Design and manufacture electrical heating elements representative of the heat losses of tomorrow’s cells and assemble them into modules

-Carry out thermal performance simulations and correlate them with test bench measurements

The customer is a US based fluid manufacturer among the worldwide leaders

Duration of the program: 15 months in 2 phases

Role of EXOES before the beginning of the program: complete definition of the evaluation and validation program of different immersion cooling fluids.

The customer’s need :

-Compare the performance of different fluids for monophasic and diphasic cooling by carrying out tests on existing prototypes and test benches at EXOES

-Evaluate the series cost of a complete cooling system for a given module architecture.

-Publish a white paper for car manufacturers explaining how to fill and drain the fluid and clean the module and battery pack

-Define the sensitivity of the fluid to water absorption and pollution

-Characterize fluid mixtures and define the method for mixing and ensuring homogeneity

-Build a battery module for comparative abuse tests between different fluids

The customer is a world leading manufacturer of fluorinated fluids

Duration of the program: 8 months

Role of EXOES before the start of the program: to understand the challenges and limitations of heat pumps in a vehicle and to define the validation program for a new fluid and then for new components.

The customer’s need :

-Validate the performance of several candidate fluids on a car manufacturer’s heat pump in drop-in mode and in detail:

-Validate chemical compatibility (metals, elastomers, polymers)

-Temperature and pressure aging of lubricants

-Miscibility/solubility of refrigerant-oil mixtures

-Comparative performance tests on a real loop (COP, capacity, compression and pumping power…)

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.